Automating an Electrodeposition Laboratory

The University of Central England wanted to fully computerise its electrodeposition laboratory. For a complete hardware and software system that improved the quality of results, kept comprehensive records of all data and events, and increased safety in the laboratory, they turned to Biodata.

The Biodata system has crucial safety features, such as shutting down equipment that is overheating, maintaining and monitoring ventilation - very important because of potential cyanide fumes, and automatically checking that all the necessary equipment is in place and properly connected.

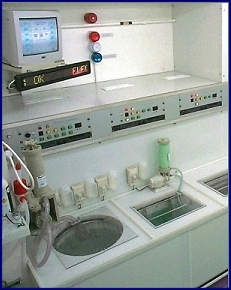

The laboratory contains 11 tanks of solution, and many parameters need to be measured and controlled in each of these tanks. During electroplating or electroforming, a layer of metal is deposited onto an object: positive metallic ions are attracted to a negatively charged object. For optimum results strict regulation of current density is needed, which is now provided by computer control. Voltage, temperature and level are all measured and appropriate action taken if safe levels crossed. All the motors, stirrers, agitators, probes, etc, are monitored throughout the processes and laboratory staff alerted to any problems. If a vital piece of equipment in a tank fails, that tank is completely shut down.

The chemicals used in the deposition process need replacing at regular intervals. The computerised system calculates when and automatically applies the correct dose. Each tank has up to 3 dosing pumps containing different solutions.

The equipment in each tank can also be controlled manually, through either a panel of switches or a software touch screen. The computer will not, however, let people perform any actions that could be dangerous. So you could not, say, switch a heater on if the level of liquid in the tank was too low.

As well as control, the system displays and logs data. Laboratory staff can see current data, or historical trend charts. Data about the entire laboratory can be seen or about individual tanks and equipment. Records are kept of all processes, logging data to disk including information about any tasks performed manually plus any alarm conditions that occurred and the steps taken to remedy the situation.

More Information

For more information on laboratory automation, contact Biodata Ltd.